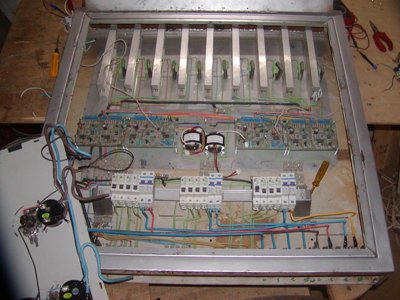

Here is an electric system with an ELC, turbine and an alternator.  This ELC is rated to manage 36 kW of 3 phase electrical power. It is equipped with an extra set of circuit boards which take over if needed. Manual over-ride control is also mounted so remote communities can still operate their plant if the ELC needs repair.  The contribution provided by the community is a key to sustainability. If they have built it, they can usually repair it too.  A finished canal built by the village community  Water gate, trashrack and forebay of a plant next to a traditional stone water mill  Usually the electricity is used for lighting and electronics. Here a villager is transporting a newly purchased TV.  Due to remote sites without roads, the community transports the equipment to the site. |

Remote HydroLight strongly believes in training and equipping the private micro-hydropower workshops. We provide standardized parts to the industry so that the turbines and ELCs are reliable and efficient.  Remote HydroLight conducts research and development experiments for the benefit of the local industry. Here the efficiency of the Chinese alternator is being tested.  Our own workshop is used for research and development as well as final fitting and inspection of hydropower components.  Turbine manufacturing requires training and blades must be positioned and welded precisely.  This private workshop has made a display of various ELCs it manufactures.  Trucks are used to transport multiple plants to the end of the road where human and animal power take over. |

A "bird eye" view of a small 4 kW power plant showing the river, stone weir, channel, forebay, penstock, powerhouse, and tailrace. Note that the water returns to the river for irrigation use. |